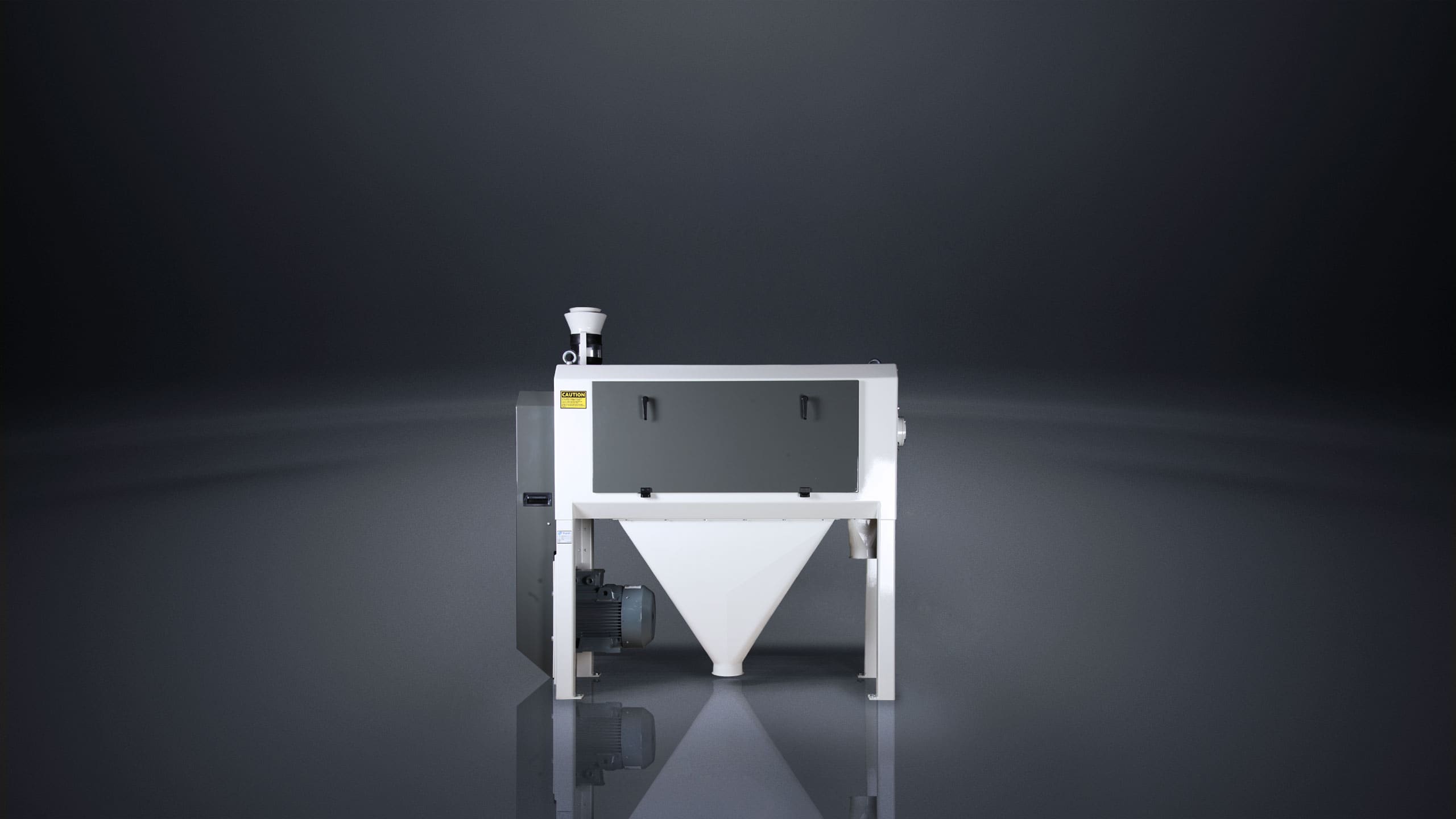

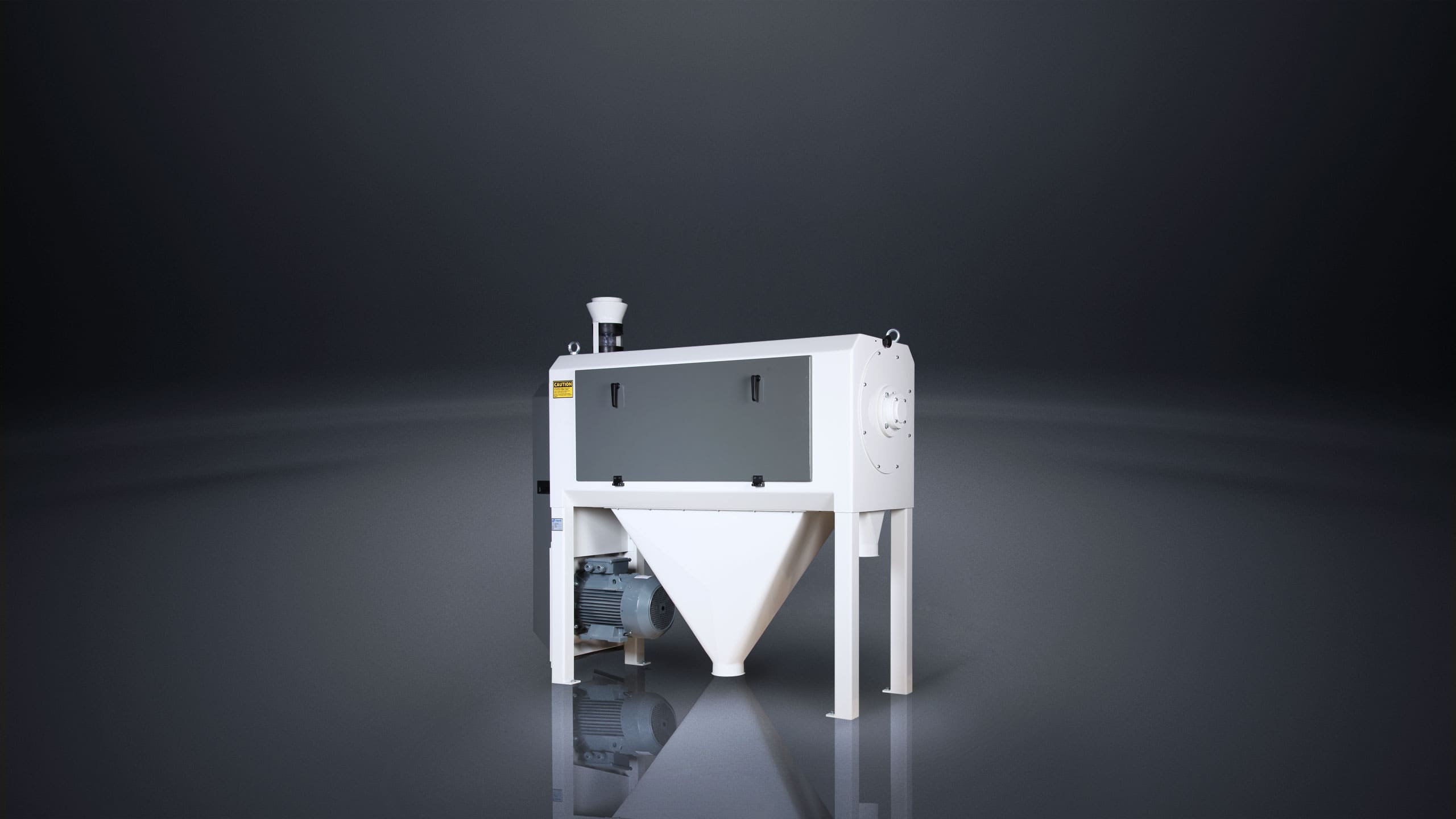

Machine, which uses a centrifugal action to gently separate the floury endosperm, attached to the bran, thus reducing to the minimum the starch content of offal and ensuring high flour yield.

The product is thrown towards the screen by means of a wing - fitted rotor, which is rotated horizontally; consequently, the flour and bran are separated from each other. Due to centrifugal force, the product is thrown towards the screen whose size is selected beforehand. During the screening process, flour passes through the screen and larger sizes of bran are directed to the discharge outlet.