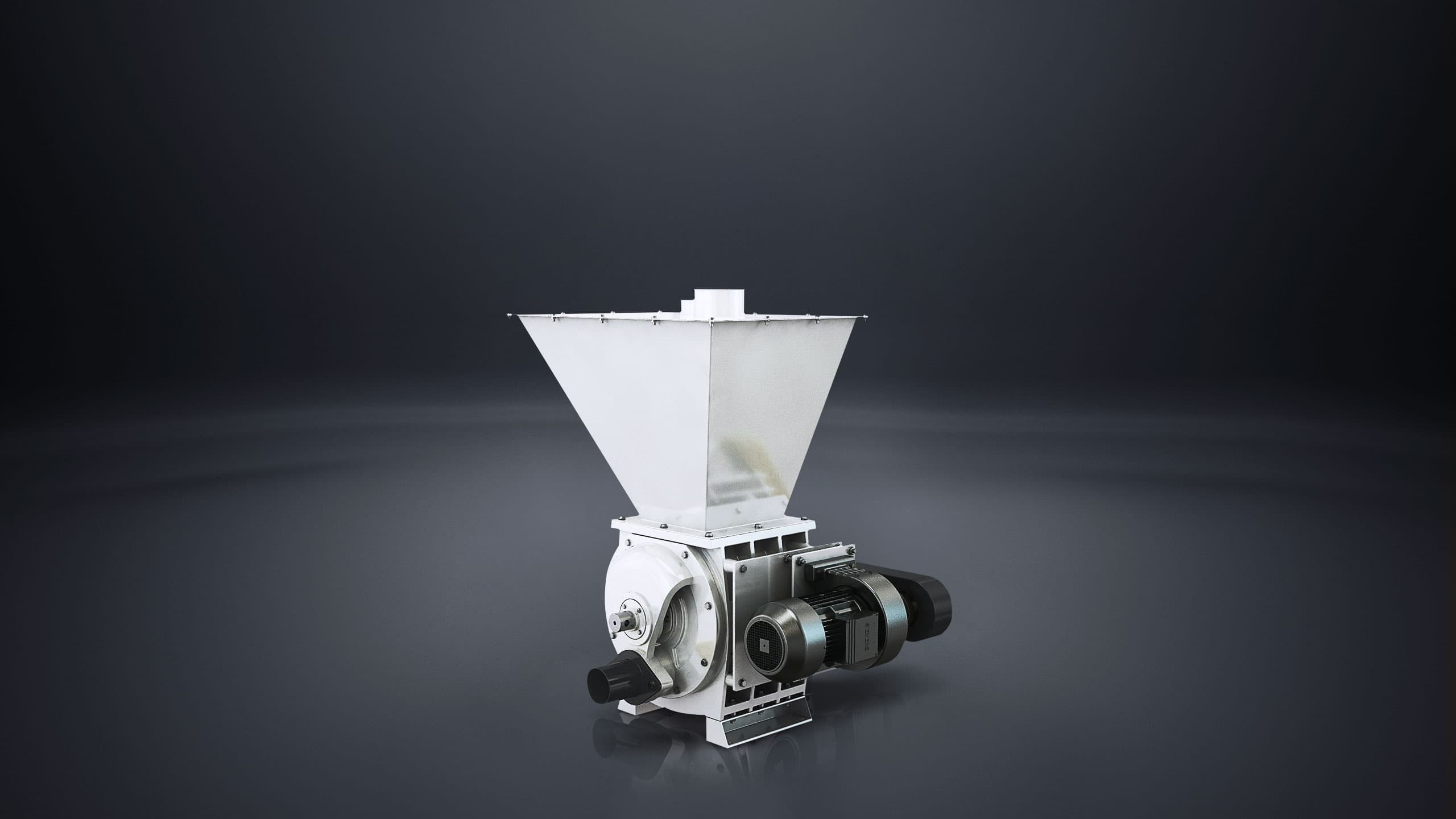

It is used to feed the product regularly and without leaking out into pneumatic conveying pipes at the pneumatic conveying systems.

The product, which enters on the airlock, flows into chambers, than will be discharged into conveying channels. The chambers are made by fixing wings on rotor shaft. Because of the precise and standard tolerances between the body housing and the rotor wings the pressurized air is prevented from leaking into the product inlet so that high efficiency and proper operation is provided. The system can be used up to 1 - 1.5 bar air pressure. By using special seals, the product is prevented from entering the shaft housing and bearings.