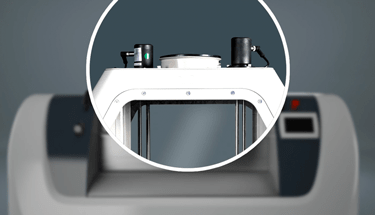

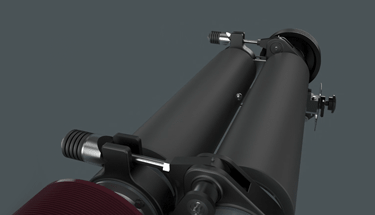

Feed Roll Capacitance Sensor

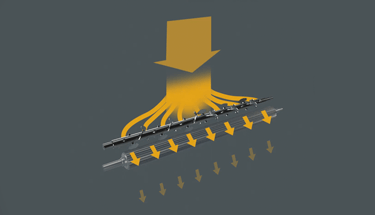

Spreading Paddle System

Auto Feed Roller Gap Adjustment System

Flexi Roll System

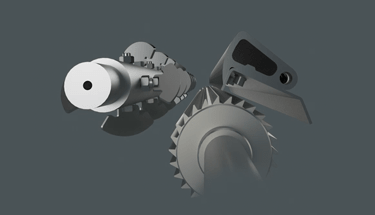

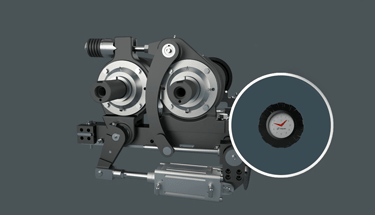

Precise Roll Adjustment System

Rear Milling Roller Speed Sensor

Feed Roll Capacitance Sensor; enables the machine to measure the product level in the feed bunker and adjust the feed roll’s speed accordingly.

This enables the machine to prevent product chokes and ensures uniform product feed during the machine operation.

Moreover, it halts the feed rolls, when there is no product in the feed bunker or flow thru the feed rolls.

Spreading Paddle System*, is a worm gear which allows the homogenous product distribution of grain over the feed rolls for better and efficient grinding process.

*Spreading System is available only in the break passages.

Auto Feed Roller Gap Adjustment System is repsonsible the proper dosage distribution of the grain to the each passage (break and reduction) for the efficient and homogenous grinding operation.

FlexiRoll System enables the machine to extend the main roll gaps to prevent any potential roll damage that may be caused by the oversized particles which enters the grinding zone.

Main Roll Adjustment System is a precise and sensitive main roll gap adjustment mechanism with a manual adjustment.

Automatic option is also available upon request.

Rear Milling Roller Speed Sensor is a precise and effective sensor to detect the revolution of the roller speed for the safety of both the machine and the operator during grinding process.

This enables the machine to prevent product chokes and ensures uniform product feed during the machine operation.

Moreover, it halts the feed rolls, when there is no product in the feed bunker or flow thru the feed rolls.