Controls product inlet to hammer mill and avoids hammer mill blockage.

Controls product inlet to hammer mill and avoids hammer mill blockage.

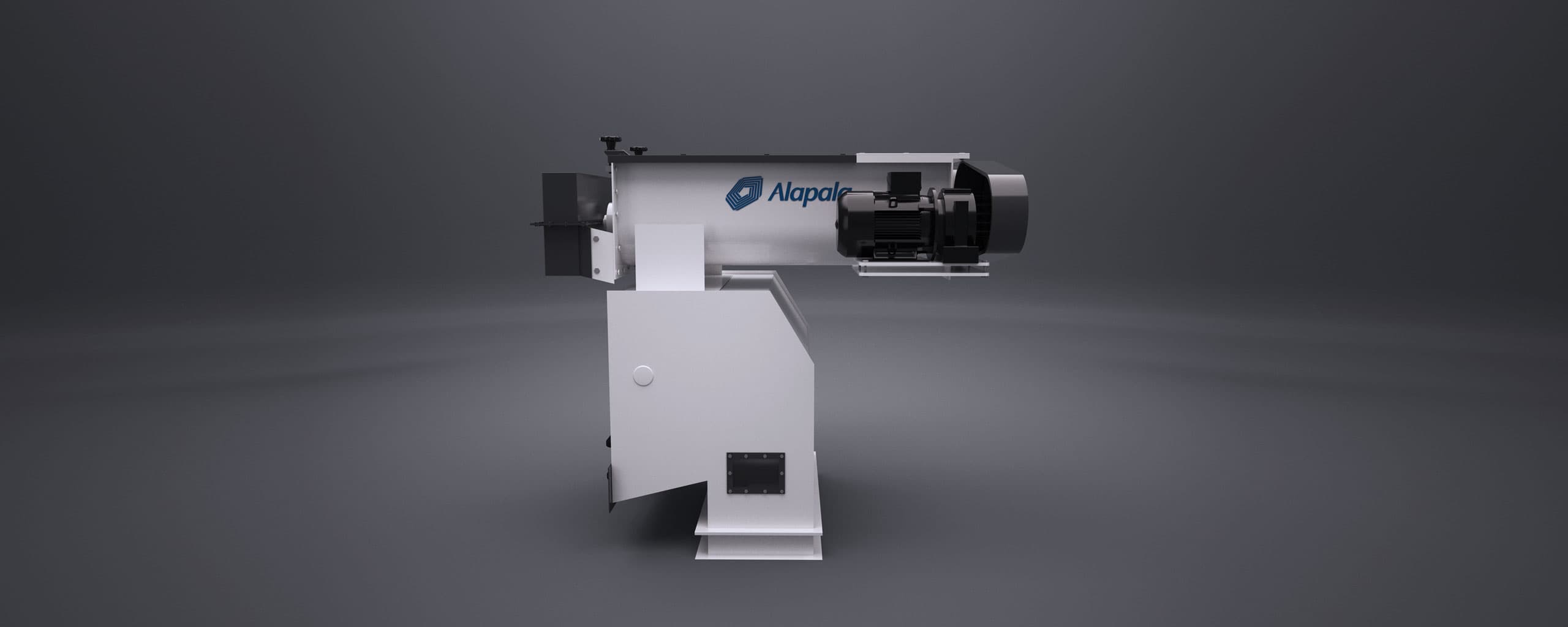

The product is fed regularly into the hammer mill by means of a suitable feeder. The size of particles is reduced by means of a rotor with beaters, which catches the product. The beating process will go on until the particles are flung through the perforated sieve, which surrounds the rotor. Then the product is collected in a hopper.

The hammer mill can be directly installed above a silo so that the product can be directly discharged into the silo. In such case, the silo must be equipped with an aspiration system, at a minimum capacity of 10 cubic meters per minute. To protect the rotor and perforated sieve a powerful magnet ought to be erected before the hammer mill.