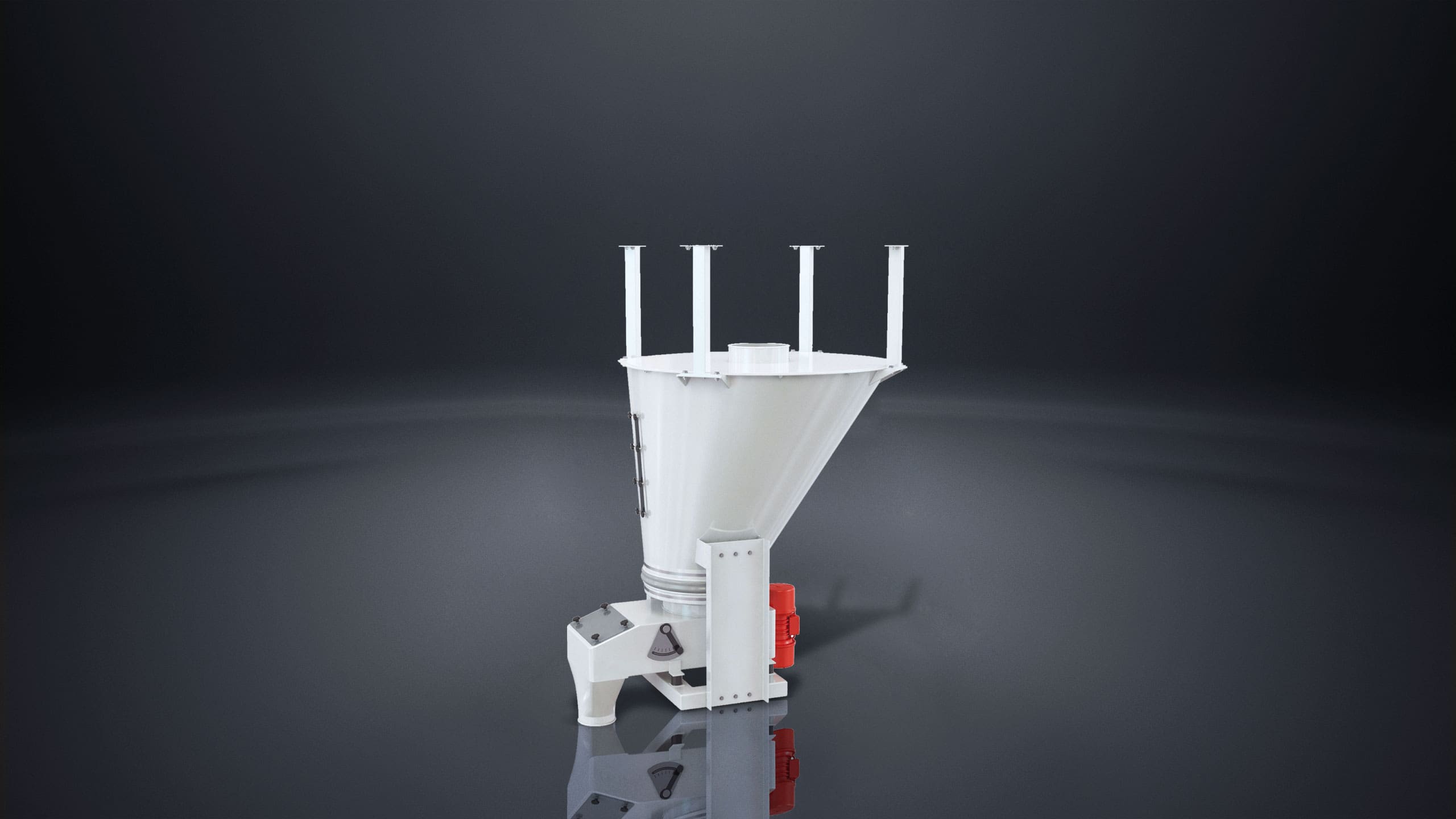

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate. For the collection of flours recovered from the filter, to feed respective pneumatic line.

The product, which is transferred from the top hopper to a vibrator feeder, is fed into a conveying element or the machine. The power unit (by a vibrator-motor) is used to obtain the required feeding by vibrating.