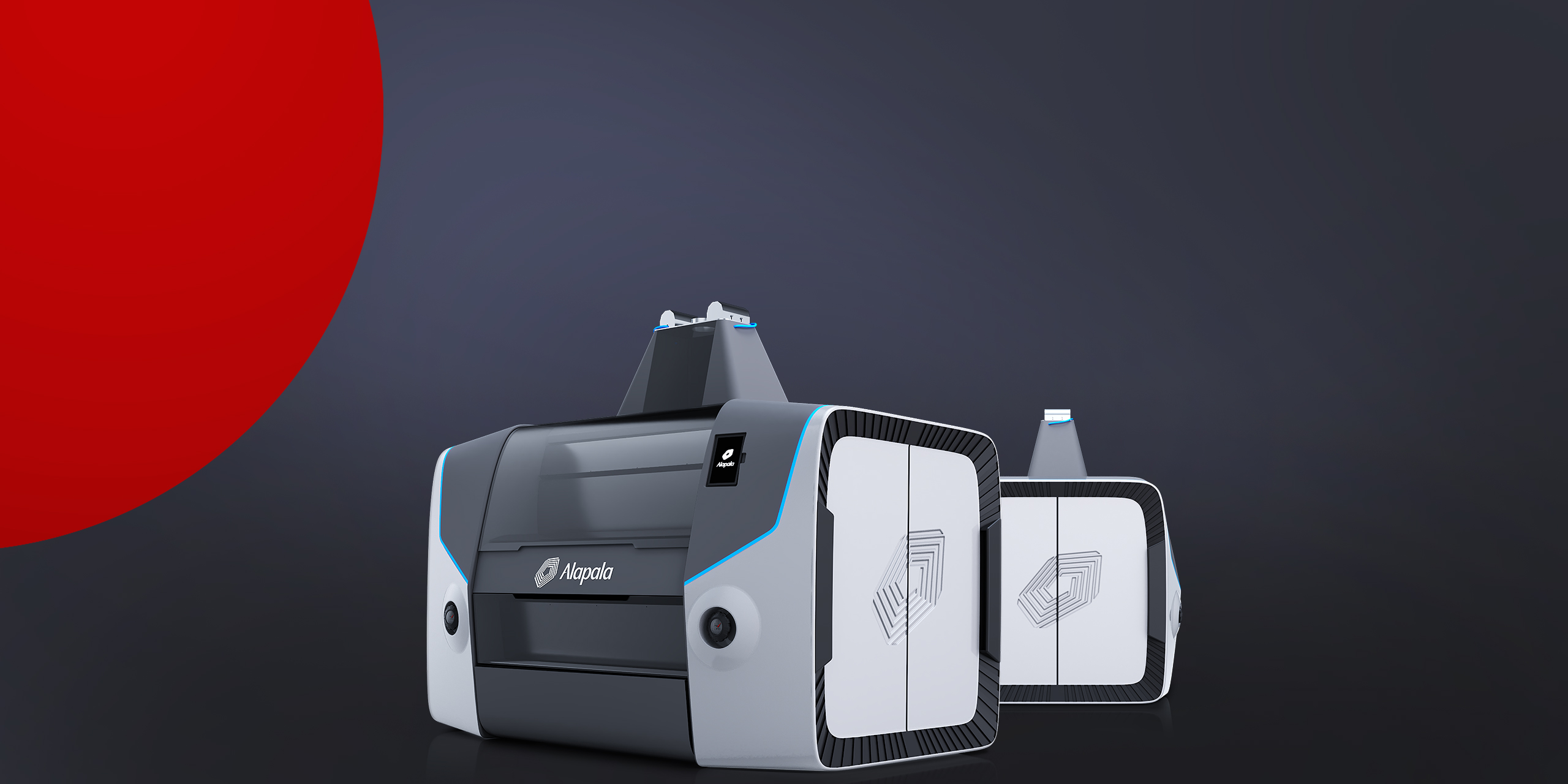

The new SIMILAGO II is the result of ALAPALA’s 60 years of experience in the milling technology and engineering of roller mills and the complete range of milling machinery. The SIMILAGO II is designed for high, continuous and consistent grinding of cereals such as wheat, maize (corn), rye, spelt, barley and sorghum. A uniform feed rate across the grinding rolls ensures a consistent grind.

The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly.

Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls.

Main motor load is constantly measured for protection against any possible damage.

The system disengages main rolls after the machine shutdown, for preventing any product blockage at the next start-up.

The rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

SIMILAGO II Facelift is built to comply with the high sanitation standards and ensure food safety.

The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk.

Stainless steel product contact surfaces is also available as an option.

Roll change operation can be performed in just 20 minutes, with is a significant reduction in down times. Also, the operation can be carried out easily with only using a standard tool set.

The system allows one-point and automatic lubrication of bearings with a proper distribution at nearly 30 different points; as another time saving, convenient, and reliable solution.

The lower chamber of feeding system can be easily set to fully open position with only a single movement. The doors and covers can also be quickly removed for easy access for cleaning.